For years, mining companies have been extracting billions of dollars worth of lithium from the Atacama region in Chile and in Argentina, where this mining has deeply affected indigenous communities. In China, graphite production for lithium-ion batteries has caused severe pollution.

Even purely from an environmental perspective, lithium-ion batteries are unacceptable. To extract 1 tonne of lithium requires a staggering 1.9 million litres of water.

In parts of the world with rich raw material salt deposits needed for the batteries, such as Argentina, Bolivia and Chile, some of the driest conditions prevail, making extraction challenging. The extraction process harms the soil and can cause toxic chemicals to leach into groundwater and potentially poison irrigation facilities.

Based on data from the International Energy Agency, for a clean electrified economy by 203o, we would need at least 250,000 to 450,000 tonnes of lithium. In 2022, the world produced only 113,000 tonnes.

It stands to reason that the world’s transition to green energy should be powered by something more eco-friendly and that lithium-ion batteries may be almost as bad a choice as fossil fuels. Technology, however, is constantly evolving and the answer to our problems may already be at hand.

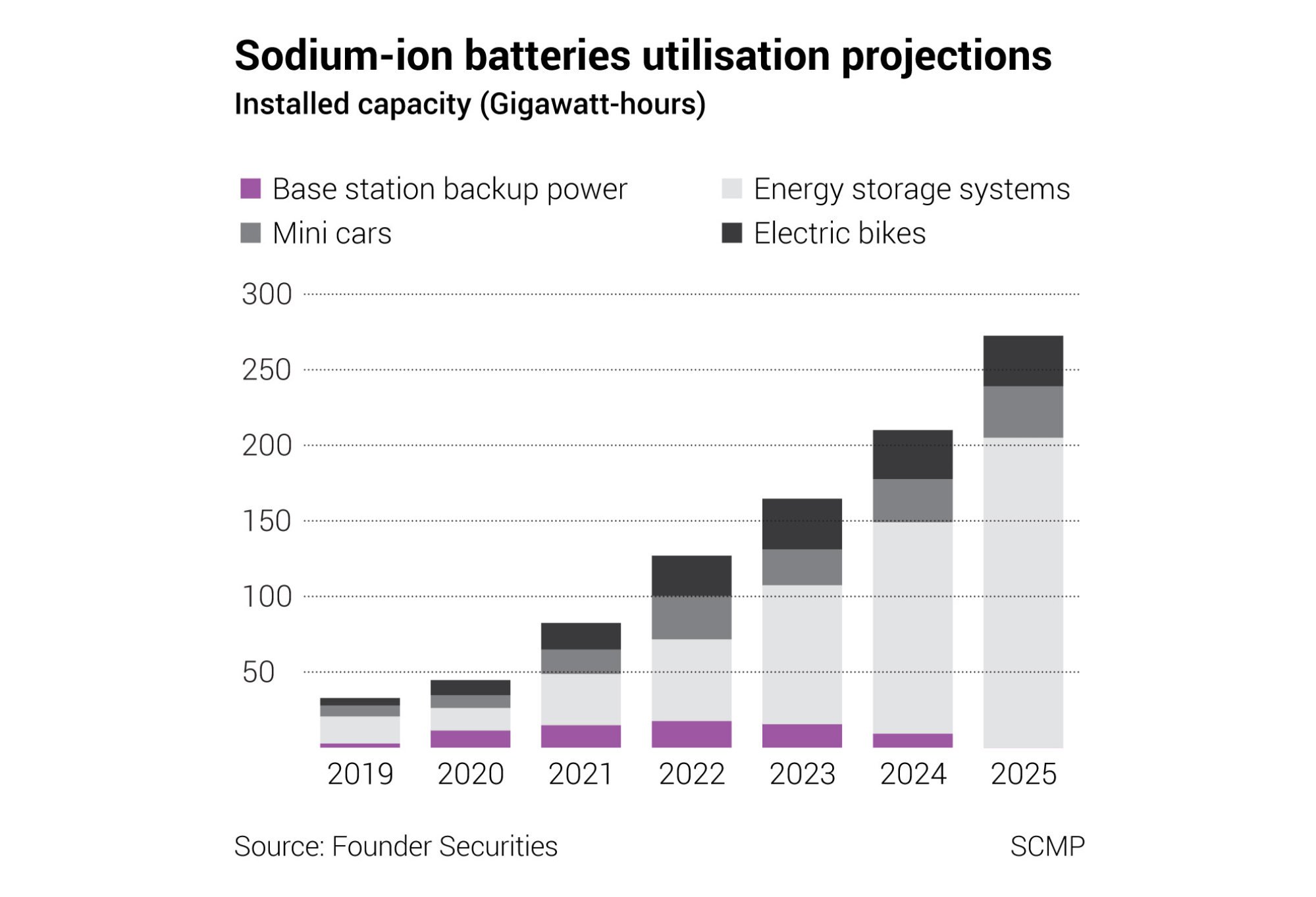

These have the potential to unsettle major EV car makers that mostly use lithium-ion batteries, as well as accelerate the process of worldwide electrification. In many ways, it’s a more practical solution and one that Asia should embrace.

Sodium-ion batteries have been found to hold up better in colder temperatures. Cold weather can significantly reduce the capacity of lithium-ion batteries. And sodium would be cheaper and is more widely available – at least 400 times more easy to procure than lithium.

While Chinese companies have already started mass producing sodium-ion batteries, with CATL and HiNA Battery Technology leading the way, the rest of Asia is waking up to this trend too.

India’s first sodium-ion batteries were launched in February. And Japan is working with the European Union to develop alternatives to lithium, with the overriding motive of reducing their dependence on China.

Other innovations in battery tech are also under way. Researchers in Germany and South Korea are collaborating on creating a battery that uses seawater. Companies in Sweden and France are also involved in sodium-ion production and exploring alternatives to lithium. Researchers in Portugal are working on glass batteries with early reports indicating that these can outperform lithium-based batteries.

If there’s one clear message that’s emerging from these innovations, it’s that Asia should invest more in researching other forms of battery technology. The region’s renewable energy sector is increasing in size, with investments expected to double to US$1.3 trillion over the next decade.

However, if Asia wants to stay ahead in the renewable energy race, it must look beyond lithium-ion technology to make progress, especially for the sake of safety.

Kamala Thiagarajan is a freelance journalist based in Madurai, southern India